|

|

|

|

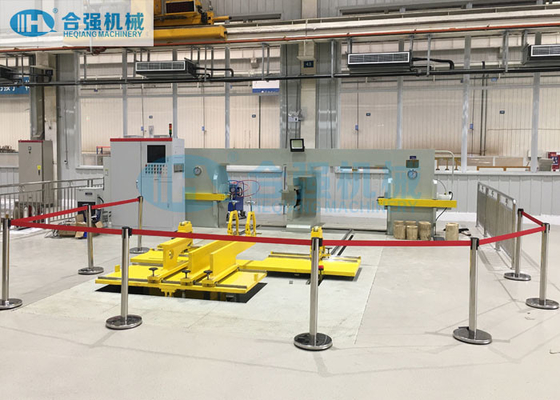

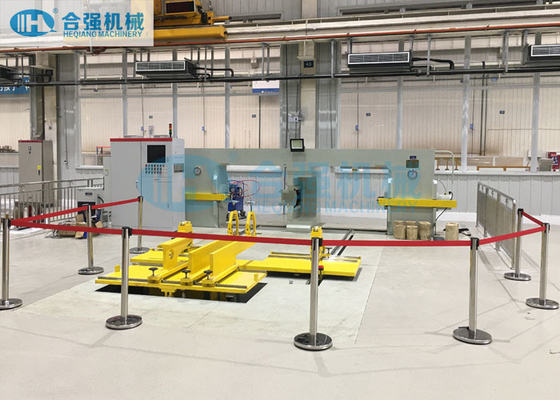

Horizontal Hydraulic Press For Disassembly Of Gearbox Bull Gear

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Wheelset Gear Assembly Press | Function: | Disassemble Wheelset Bull Gear |

|---|---|---|---|

| Application: | Railway Depots, Rolling Stock Enterprises | Number Of Ram Cylinder: | 2pcs (1 Left + 1 Right) |

| Main Cylinder Force: | 3150 KN | Sub-cylinder Force: | 800 KN |

| Piston Stroke: | 700 Mm | Stroke Control Accuracy: | ≤ 0.1 Mm |

| Warranty: | One Year | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Highlight: | 3150kN Horizontal Hydraulic Press,Wheelset Gear Assembly Press 3150kN,Gearbox Wheelset Gear Assembly Press |

||

Horizontal Hydraulic Press For Disassembly Of Gearbox Bull Gear,

Double Cylinder Wheelset Gear Press Machine, Railway Wheel Demount Press

Application scope:

This Hydraulic Press For Disassembly Of Large Bull Gear is used to disassemble the bull gear of the gearbox and its surrounding components off from the axle. It's applicable for EMU wheelsets with gearbox. Only required one operator to complete the opeation. A high-pressure oil injection system is provided for easy dismounting.

Technical Parameters:

| Maximum cylinder force | 3150 kN |

| Number of Ram cylinder | 2 pcs (1 left + 1 right) |

| Piston stroke | ≥ 700mm |

| Pressing speed | 0~300 mm/min |

| Fast forward and Return speed | 1000 mm/min |

| Concentricity of cylinders' centerline (by measurement) | ≤ 0.4 mm (in non-work status) |

| Max load of the centering device | 2 tons |

| Stroke control accuracy | ≤ 0.1 mm |

| Re-positioning accuracy | ≤ 0.1 mm |

| Maximum hydraulic system pressure | 25 MPa |

| Maximum capacity of the support carriage | 2.5 tons |

| High-pressure injection equipment | 1 set, Max. pressure 200 MPa |

| Main power supply (AC 3 phase) | 380V/50HZ or as per required |

(*Remarks: The detailed gearbox dimensions shall be provided for design work after the contract awarded.)

Main Features:

- The hydraulic press is a horizontal structure design and will be installed in a foundation pit.

- The bull gear press is used to dismount the bull gear off from the axle. It's applicable for EMU wheelsets with gearbox.

- Only one operator required to complete the whole dismounting procedures.

- The press is mainly composed of horizontal gantry frame, main cylinders, loading and unloading support carraige, displacement detection device, hydraulic system, electrical control system, high-pressure injection system and the relavent toolings etc.

- The main body is all steel welding structure and carried out stress relief annealing treatment. With sufficient strength and rigidity.

- Centering devices for Axle center hole positioning.

- With Automatic and Manual operation mode for optional.

- Siemens S7 PLC and AdvanTech industrial computer to control the machine operation.

- With high-precision pressure sensor and displacement sensor for signal collection.

- Automatically record, save and print the pressing curve.

- A support carraige for transferring the axle with gearbox into or out from the machine.

- A high-pressure injection pump for easy dismounting. (Brand: MAXIMATOR, Max capacity:200MPa)

Technical Documents:

The following technical documents will be supplied along with the machine when delivery in 3 hard copies and 1 soft copy in English language:

- Operating and maintenance instruction manual.

- General arrangement drawing, Foundation drawing.

- Hydraulic schematic diagram, Electrical schematic diagram

- Spare part list, Special tool list.

- Product certificate

Warranty & After-sale Service:

One year of free warranty and lifetime maintenance for the equipment for your purchased equipment. During the warranty period, only due to design defects, manufacturing quality, and quality of purchased parts, our company is responsible for free maintenance. The company provides the required replacement parts (except for consumable parts). Over the warranty period, repairs only are charged at the cost price. At the same time, you will enjoy a lifetime software upgrade from the date of purchase; our engineers will provide a quick response when service is required.

![]()

![]()

![]()

![]()

Contact Person: Freeman Hu

Tel: +86-15337398239

-

HQ59 Type Railway Gearbox Bearing Dismantling Machine

-

HQ58 Type Railway Gearbox Bearing Press-fitting Machine

-

Railway Bull Gear Press Machine Dismounting Gear Siemens PLC Control

-

315t Wheelset Gear Assembly Press Railway Bull Gear Press-off Machine

-

Railway Bull Gear Press Mounting Machine Wheelset Gear Assembly Press

-

350 Ton Locomotive Wheelset Gear Assembly Press