|

|

|

|

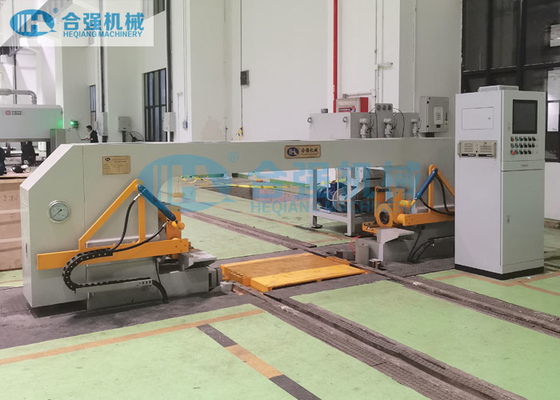

Max 60 Tons Railway Bearing Puller / Pusher Hydraulic

|

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Bearing Puller/Pusher | Application: | Wheelset Maintenance Workshop |

|---|---|---|---|

| Function: | Bearing Assembly And Disassembly | Max. Cylinder Force: | 60 Tons |

| Cylinder Stroke: | ≥ 500mm | Operation Mode: | Automatic |

| Cycle Time For Pressing-on: | ≤ 4 Minutes Per Axle | Installed Power: | ≤ 25kW |

| Highlight: | Railway Bearing Puller,Max 60t Bearing Puller,Hydraulic Railway Bearing Pusher |

||

Hydraulic Bearing Extractor And Installer , Railway Bearing Puller/Pusher

Automatic Wheelset Bearing Mounting And Dismounting Press

Bearing Mount and Dismount Press, Bearing Assembly and Disassembly Press

Application Scope:

This Hydraulic Bearing Extractor And Installer is mainly used to install and remove the rolling bearings of the railway rolling stocks. It is generally used in wheelset/bogie maintenance depot and workshop. With curve recording system. Only one operator is required to run the press.

Technical Parameters:

| Bearing Extractor And Installer: | |

| - Maximum cylinder force | 60 tons |

| - Ram cylinder Qty | 2 pcs |

| - Maximum cylinder stroke | ≥ 500 mm |

| - Pressing speed | 0~6 mm/s |

| - Cycle time for mounting | ≤ 4 minutes per axle |

| - Hydraulic system pressure | ≤ 25 MPa |

| - Total installed power | ≤ 25 kW |

| - Resolution of the displacement sensor | 0.1 mm |

| - Coaxiality of the ram cylinders | ≤ 0.4 mm |

| Applicable wheelset: | |

| - Wheelset weight | ≤ 3000 kg |

| - Track gauge | 1435 mm |

| - Axle length | 2000 ~ 2400 mm |

| - Wheel diameter | 750 ~ 1100 mm |

| Working conditions: | |

| - Power supply (3 phase, AC) | 380V/50Hz, or as per required |

| - Ambient temperature | -5~45 ℃ |

| - Relative humidity | ≤ 95% |

| - Workplace | Interior workshop |

(*Remarks: The above parameters are indicative and can be modified as per customer's actual requirements. The customer must provide us the detailed wheelset drawings for design work after contract award.)

Machine Structure & Features:

The bearing assembly and disassembly press is mainly composed of main frame, left/right cylinders, dismounting claw devices, wheelset lifting device, push wheel device, calibration device, hydraulic system, measuring and electrical control system etc.

- This Wheel Bearing mount and dismount press will be installed in a foundation pit.

- It's able to mount and dismount the rolling bearings onto / off from the axles.

- Only a single positioning to complete the fitting and removal of both bearings.

- Automatical mounting and dismounting both bearings simultaneously with a single positioning.

- Automatical mounting and dismounting single bearing separately.

- Manually complete the mounting and dismounting as per the working steps. (used during maintenance and commissioning).

- Automatic mounting and dismounting under non-load (used in test run).

- Veto for wrong input and incorrect operation.

- Overall welding structure, with sufficient strength and rigidity.

- Double cylinders for mounting and dismounting. With special anti-upsetting centre devices.

- Intelligent lifting platform. It's equipped with wheel locking mechanism, so as to avoid wheelset runout during mounting and dismounting and ensure the stability of the pressing force.

- Siemens S7 PLC to control the operation.

- User-friendly human machine interface.

- The operation system can generate, record, save and print the pressing curves.

- On-line passing-through arrangement, the wheelset can be pushed out automatically after the bearing is pressed.

- Unique hydraulic servo system to achieve the variable pressing speed and ensure the stable and reliable pressure during opeation.

Warranty & After-sale Service:

- The warranty lasts for 1 (one) year from the date of the Site Acceptance Test of the Equipment.

- During the warranty, the Manufacturer shall be responsible for the damage due to the defects in design and manufacture.

- After the warranty period, the Manufacturer will provide a wide range of technical support and spare parts with reasonable prices.

Cooperation contact:

If you are interested in our machines or any assistance required, please feel free to contact us for more information.

![]()

Contact Person: Freeman Hu

Tel: +86-15337398239

-

Railway Portable Wheel Bearing Press , Bearing Puller And Pusher

-

Stationary Wheel Bearing Press Machine For Automatic Mounting

-

750kN Stationary Bearing Dismount Press

-

Double Cylinder Wheel Bearing Press Machine For Disassemble Railway Bearings

-

100 Ton Railway Bearing Press Machine For Mounting Dismounting

-

60 Ton Cylinder Force Wheel Bearing Press Machine