|

|

|

|

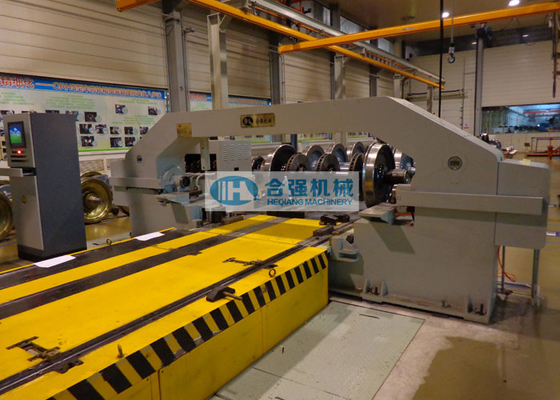

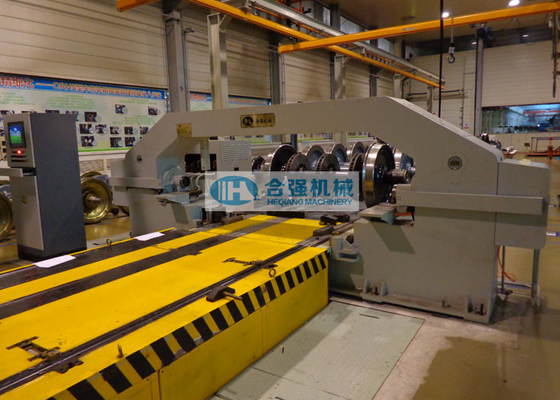

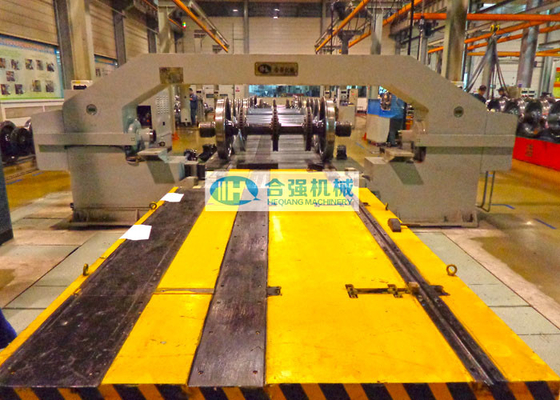

2250mm Wheelset Bearing Mounting Press For Railway Vehicles

|

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Wheel Bearing Press Machine | Application: | Railway Depots, Rolling Stock Enterprises |

|---|---|---|---|

| Function: | Mount Railway Rolling Bearings | Operation Mode: | Automatic And Manual |

| Ram Cylinder Qty: | 2 Pcs | Operator Required: | One Operator |

| Warranty: | One Year | After-sales Service: | Engineer Available To Service Machiney Oversea |

| Highlight: | 600kN Wheelset Bearing Mounting Press,Railway Vehicles Wheelset Bearing Mounting Press,15kW Railway Bearing Press |

||

Railway Automatic Wheel Bearing Press Machine For Mounting Various Railway Rolling Bearings

Application scope:

This Wheelset Bearing Mounting Press is applicable for mounting the rolling bearings onto the axle. It can mount either single end bearing separately, also can mount both ends bearings simultaneously. It's suitable for all railway vehicles (passenger cars, wagons, metros, EMU etc.). It can record, save and print the pressing curve (Pressure vs displacement, pressure vs time). It's only required one operator to operate the press.

Technical parameters:

| Maximum Mounting force | 600 kN |

| Ram cylinder Qty | 2 pcs |

| Maximum single cylinder stroke | 550 mm |

| Pressing speed | 0~4 mm/s (adjustable) |

| Resolution of pressing force display | Not more than 0.1 kN |

| Resolution of displacement sensor | 0.01 mm |

| Dection accuracy of the pressure sensor | 0.25%FS |

| Working cycle time | Not more than 4 minutes per axle |

| Maximum hydraulic system pressure | 22 MPa |

| Noise level during working | Not more than 75dB |

| Installed power | 15 kW |

| Wheelset weight | 3000 kg |

| Track gauge | 1435 mm |

| Applicable axle length | 2150 ~ 2250 mm |

| Applicable wheel diameter | 810 ~ 920 mm |

| Inner diameter of the bearing to be pressed | 120 mm, 130 mm |

| Outer diameter of the bearing to be pressed | 230 mm, 240 mm |

(*Above parameters are indicative, and can be modified as per customer's requirements.)

Machine features:

- This bearing press machine is mainly composed of overall gantry frame, main cylinder, lifting device, guide device, measurement device, bearing positioning device, hydraulic system and electrical control system etc.

- No foundation pit required.

- Gantry frame structure is of Pass-through type design.

- With lifting type work platform;

- Double-head ram cylinders, installed with special patented upsetting centres at the end.

- Automatic component positioning.

- Mounting both end bearings with a single positioning.

- Automatic mounting separately of single end bearing.

- Automatic mounting simultaneously of both end bearings.

- Automatic recording of pressing curve and can print the curve.

- It can automatically and real-time detect and record the pressing force, adhesion force, pressure difference and holding time during bearing mounting, and automatically judgement: qualified or not.

- The press can automatically judge whether the bearing is mounted into position, and start the pressure holding.

- It has the functions of data storage, curve recording, intelligent judgment, curve merging, automatic HP printing of A4 paper in the form of graphics, etc.

- Siemens PLC and AdvanTech IPC to control the operation.

- Unique hydraulic servo system.

Warranty & After-sale Service:

One year of free warranty and lifetime maintenance for the equipment for your purchased equipment. During the warranty period, only due to design defects, manufacturing quality, and quality of purchased parts, our company is responsible for free maintenance. The company provides the required replacement parts (except for consumable parts). Over the warranty period, repairs only are charged at the cost price. At the same time, you will enjoy a lifetime software upgrade from the date of purchase; our engineers will provide a quick response when service is required.

Cooperation contact:

If you are interested in our machines or any assistance required, please feel free to contact us for more information.

![]()

![]()

Contact Person: Freeman Hu

Tel: +86-15337398239

-

Railway Portable Wheel Bearing Press , Bearing Puller And Pusher

-

Stationary Wheel Bearing Press Machine For Automatic Mounting

-

750kN Stationary Bearing Dismount Press

-

Double Cylinder Wheel Bearing Press Machine For Disassemble Railway Bearings

-

100 Ton Railway Bearing Press Machine For Mounting Dismounting

-

60 Ton Cylinder Force Wheel Bearing Press Machine